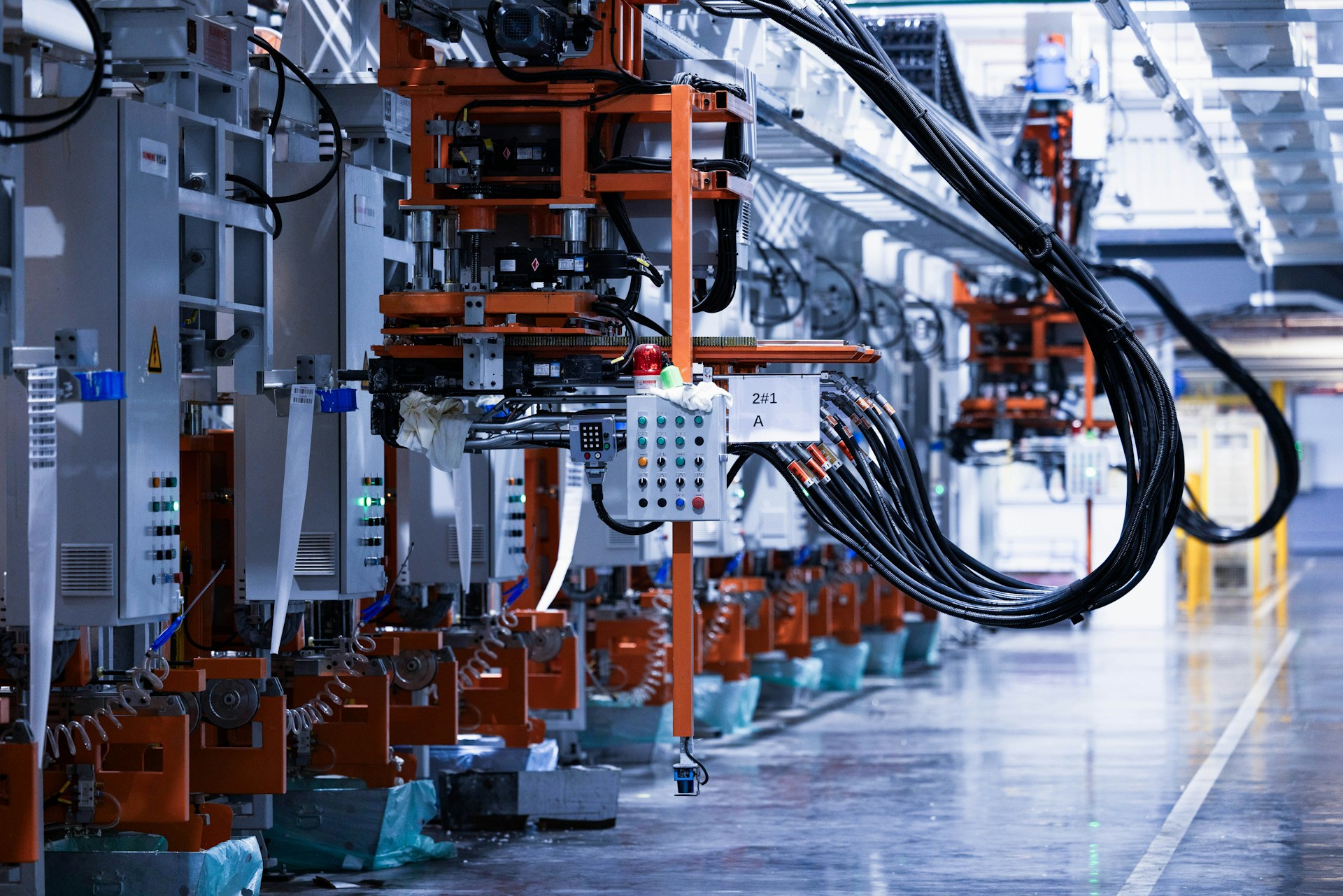

Custom manufacturing has emerged as a pivotal solution for businesses seeking tailored approaches to meet their unique needs.

Whether it’s producing niche products, overcoming industry-specific challenges, or scaling specialized operations, custom manufacturing offers flexibility and adaptability that traditional production cannot achieve.

This blog explores how businesses benefit from custom manufacturing, examines its diverse applications, and offers insights into why it has become essential for modern enterprises.

What Is Custom Manufacturing?

Custom manufacturing refers to the process of creating products or components that are specifically designed and produced to meet individualized specifications.

Unlike mass manufacturing, which emphasizes uniformity and high-volume output, custom manufacturing focuses on producing tailored solutions to fit precise requirements.

From small-batch production to bespoke designs, the scope of custom manufacturing spans industries such as aerospace, healthcare, construction, and consumer goods.

This highly adaptable approach ensures that businesses can address specific challenges, stand out in competitive markets, and deliver enhanced value to their customers.

Benefits of Custom Manufacturing for Businesses

Custom manufacturing offers a range of tangible benefits that make it an appealing choice for organizations with specialized needs.

Tailored Solutions for Unique Requirements

One of the core advantages of custom manufacturing is the ability to create products that align perfectly with the unique demands of a business. Whether it’s size, shape, material, or functionality, custom solutions ensure that businesses receive exactly what they need without compromise.

For example, a healthcare company may require equipment designed to meet stringent industry regulations. By working with a custom manufacturer, they can ensure those specifications are met while maintaining quality and compliance.

Increased Flexibility in Design and Production

Unlike standardized production, custom manufacturing allows for adaptability throughout the design and manufacturing process. Businesses can make changes, tweak designs, or incorporate new features as they go.

This level of flexibility is particularly valuable for emerging startups or industries where consumer preferences and market trends shift rapidly.

Higher Quality and Precision

Custom manufacturing often involves close collaboration between clients and manufacturers, ensuring that products are made with precision and attention to detail. Specialized production techniques and high-quality materials further ensure the durability and reliability of the finished products.

For sectors like aerospace or medical devices, where quality is non-negotiable, the precision provided by custom manufacturing proves invaluable.

Improved Competitive Advantage

With custom manufacturing, businesses can create cutting-edge, innovative products that differentiate them from their competitors. Offering something truly unique helps attract niche audiences, secure loyalty, and establish leadership in the market.

For example, a furniture company that uses custom manufacturing to produce one-of-a-kind designs can appeal to high-end clientele seeking exclusivity and luxury.

Efficient Use of Resources

Custom manufacturing reduces waste by producing only what is needed, and when it is needed. This resource efficiency not only saves costs but also aligns with sustainable practices sought after by eco-conscious customers.

Whether it’s minimizing raw material usage or eliminating excess production, custom manufacturing lowers environmental impact while benefiting the bottom line.

Scalability for Business Growth

Many custom manufacturers can cater to both small and large-scale needs, allowing businesses to grow seamlessly. Starting with small-batch production, they can scale up operations when demand increases, ensuring a smooth growth trajectory.

Industries Benefiting from Custom Manufacturing

Custom manufacturing isn’t limited to a single sector. Its versatility ensures applications across diverse industries, each benefiting from specialized production.

Aerospace

The aerospace industry relies on custom manufacturing for high-precision components critical to safety and performance. From specialized engine parts to lightweight materials for jets, this sector extensively leverages tailored solutions.

Healthcare

Healthcare organizations often require custom-made medical devices, prosthetics, and surgical tools designed to cater to individual patients or procedures. Tailored solutions improve patient outcomes while ensuring compliance with stringent regulatory standards.

Automotive

Custom manufacturing supports the automotive industry in creating prototype parts, specialty components, and luxury features. This ensures that automakers can deliver cutting-edge innovations and premium-quality vehicles.

Consumer Products

From personalized furniture to bespoke electronics, custom manufacturing allows consumer brands to offer unique products that resonate with targeted audiences. The rise of customization in consumer markets reflects the growing demand for personalized goods.

Construction

Custom manufacturing enables the production of prefab construction materials, specialized infrastructure components, and bespoke designs for architectural projects. These tailored solutions align with the unique demands of each construction site.

Technology

The tech industry frequently relies on custom manufacturing for devices, specialized hardware, or components with unique configurations. Whether it’s adapting to the latest innovation or meeting non-standard requirements, tailored options empower the sector.

Steps to Implement Custom Manufacturing

Businesses interested in adopting custom manufacturing should follow these strategic steps to ensure success.

Identify Specific Needs

The first step is defining the unique requirements of your products or components. Detail the specifications, performance goals, and materials needed to provide manufacturers with a clear understanding of your objectives.

Choose a Reliable Manufacturer

Partnering with an experienced custom manufacturer is critical. Look for companies with proven expertise, strong credentials, and the ability to deliver quality custom solutions on time.

Design Collaboration

Custom manufacturing often involves iterative design. Providing feedback during the design phase ensures the final product meets and exceeds expectations.

Understand Costs

While custom manufacturing may involve higher up-front costs compared to mass production, its long-term benefits in terms of quality, differentiation, and value often outweigh the expense. Clear communication with the manufacturer on budget constraints is essential.

Optimize Production

Work closely with the manufacturer to ensure an efficient production process, focusing on minimizing waste, selecting high-quality materials, and meeting timelines.

Monitor and Evaluate

Consistent monitoring during production ensures quality and alignment with specifications. Post-production evaluation provides valuable insights for ongoing improvement.

Custom Manufacturing Drives Innovation and Success

Custom manufacturing has evolved into more than just a solution for specialized needs. It is a powerful tool that allows businesses to innovate, compete, and thrive while fostering sustainable practices.

When businesses align their specific requirements with cutting-edge custom solutions, they achieve outcomes that are not only practical but also strategically advantageous.

Whether you’re in healthcare, technology, consumer goods, or another sector, custom manufacturing could be the key to unlocking your competitive edge. Start exploring tailored production solutions that cater precisely to your unique needs. Click here to learn more!