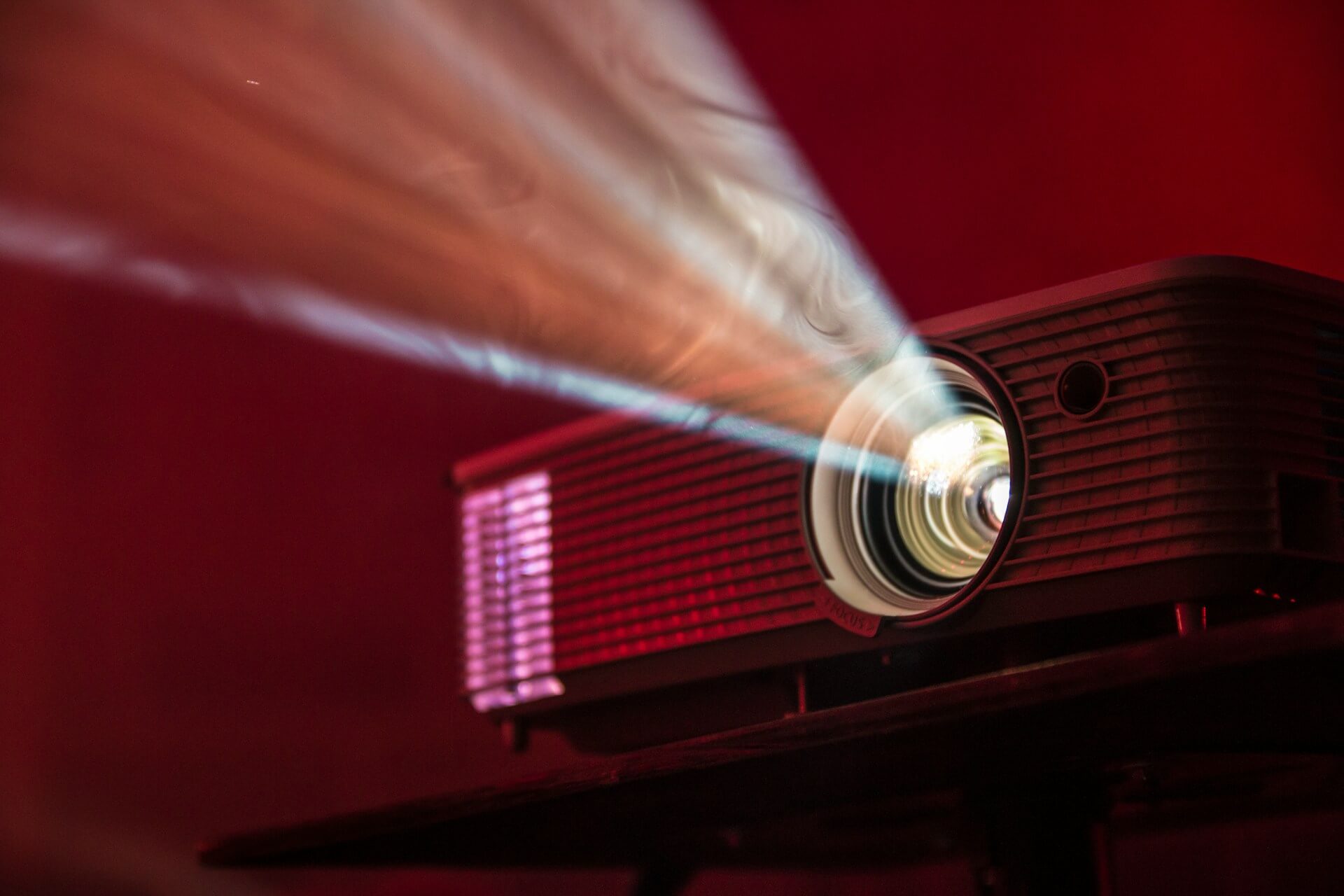

LED screens have become essential components in everything from digital signage and entertainment systems to industrial applications.

When these displays suddenly stop working, the disruption can be costly and frustrating. Understanding the root causes of LED screen failures empowers you to identify problems quickly and determine whether professional LED repair services are necessary.

Modern LED technology is generally reliable, but several factors can cause screens to malfunction or fail. From power supply issues to environmental damage, each type of failure presents distinct symptoms that can help you diagnose the problem.

Recognizing these screen issues early often means the difference between a simple fix and a complete replacement.

This comprehensive breakdown covers the six most common reasons LED screens stop working, along with troubleshooting steps you can take before calling in professional help.

Whether you’re dealing with a blank screen, flickering display, or color distortion, these insights will help you understand what’s happening and plan your next steps.

Power Supply Problems Create the Most Screen Issues

Power-related failures account for the majority of LED screen malfunctions. These problems can manifest in several ways, from complete blackouts to intermittent flickering that gradually worsens over time.

Inadequate Power Delivery

LED screens require consistent voltage and current to function properly. When power supplies fail to deliver adequate electricity, displays may:

- Turn on briefly before shutting down

- Display dim or flickering images

- Show only partial sections of the screen

- Fail to power on entirely

Power Supply Component Failure

Internal components within the power supply unit can degrade over time. Capacitors, transformers, and voltage regulators are particularly susceptible to failure, especially in environments with temperature fluctuations or electrical surges.

Cable and Connection Issues

Loose power connections or damaged cables can interrupt power delivery. Check all power cables for visible damage, ensure connections are secure, and verify that power outlets are functioning correctly before assuming internal component failure.

Driver Circuit Malfunctions Cause Display Irregularities

LED driver circuits control how individual pixels receive power and display information. When these circuits fail, you’ll notice specific patterns of malfunction that distinguish driver issues from other problems.

Symptoms of Driver Circuit Problems

Driver circuit failures typically produce:

- Dead pixel clusters in regular patterns

- Entire rows or columns of non-functioning LEDs

- Color channel failures affecting the red, green, or blue display

- Brightness inconsistencies across the screen

Environmental Stress on Drivers

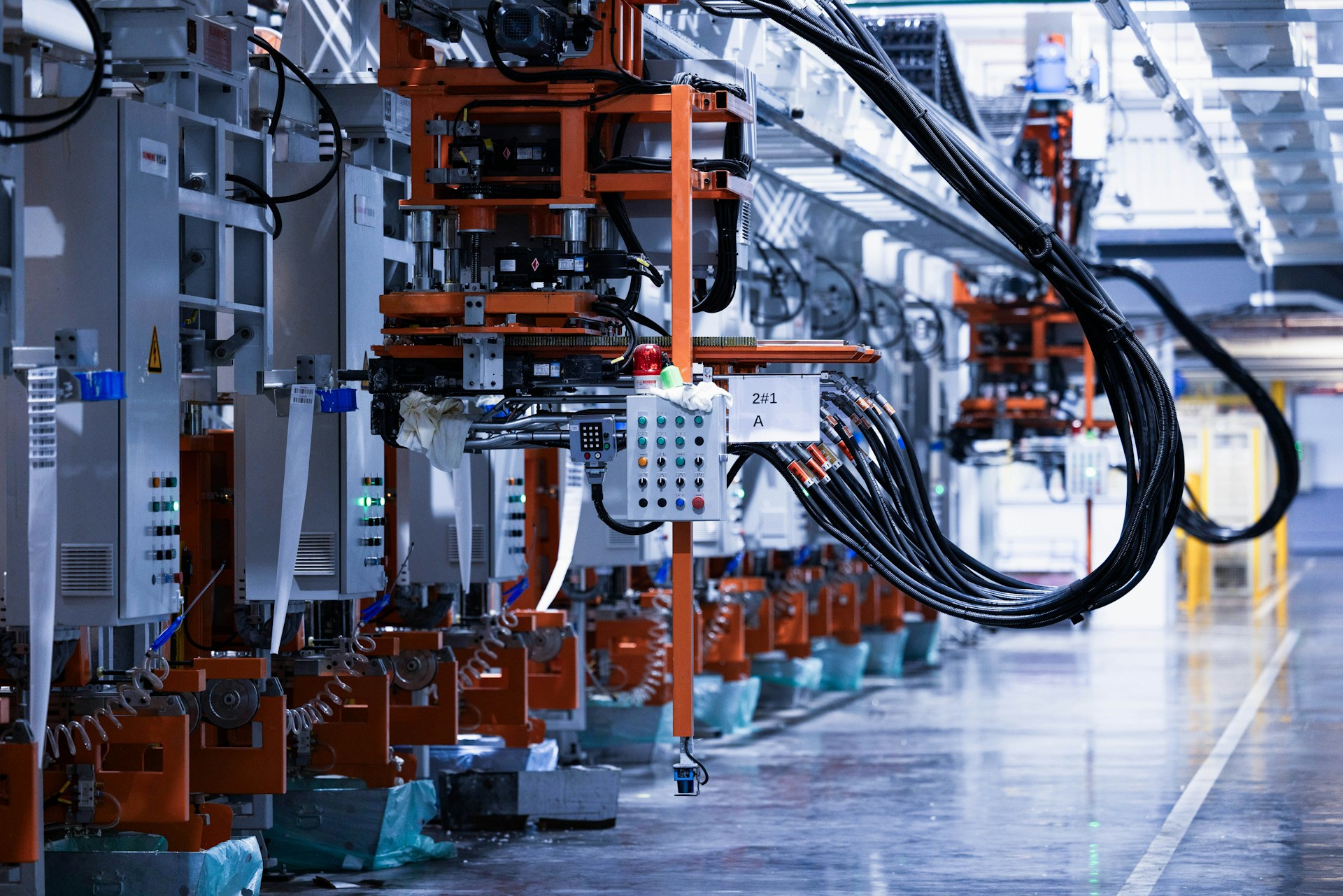

Driver circuits are sensitive to heat, humidity, and electrical interference. Poor ventilation around LED displays can cause driver components to overheat and fail prematurely. Similarly, electrical noise from nearby equipment can disrupt driver circuit operation.

Age-Related Driver Degradation

Over time, driver circuits naturally degrade through normal use. Older LED screens may experience gradual driver failures, with symptoms becoming more pronounced as components approach the end of their operational lifespan.

Overheating Damages LED Components Permanently

Heat is one of the biggest enemies of LED screen longevity. Excessive temperatures can cause immediate failures or accelerate component degradation, leading to premature screen replacement.

Heat Sources That Affect LED Screens

Several factors contribute to LED screen overheating:

- Inadequate ventilation around the display

- Direct sunlight exposure on outdoor installations

- Malfunctioning cooling fans or heat sinks

- High ambient temperatures in enclosed spaces

- Excessive brightness settings that generate additional heat

Thermal Protection Features

Modern LED screens include thermal protection circuits that shut down displays when temperatures exceed safe limits. If your screen turns off unexpectedly during operation, overheating may be the cause. Allow the display to cool completely before attempting to restart.

Long-term Heat Damage

Chronic exposure to high temperatures causes gradual LED degradation, resulting in color shifts, brightness loss, and eventual pixel failure. Regular temperature monitoring and proper ventilation are essential for preventing heat-related screen issues.

Physical Damage Compromises Screen Integrity

LED screens are more durable than traditional displays, but physical impacts can still cause significant damage. Understanding different types of physical damage helps determine repair feasibility.

Impact Damage Patterns

Physical impacts create characteristic damage patterns:

- Cracked LED modules with radiating fracture lines

- Dead zones corresponding to impact points

- Loose connections are causing intermittent operation

- Visible surface damage on protective covers

Environmental Physical Stresses

Outdoor LED screens face additional physical challenges:

- Wind loading that can loosen mounting hardware

- Hail or debris impacts during severe weather

- Thermal expansion and contraction cycles

- UV radiation degrades protective materials

Installation-Related Physical Issues

Improper installation can create ongoing physical stresses that eventually cause screen failure. Insufficient structural support, improper cable management, and inadequate weather protection all contribute to premature physical damage.

Environmental Factors Accelerate Component Degradation

Environmental conditions play a crucial role in LED screen reliability. Moisture, temperature extremes, and atmospheric contaminants can all cause screen issues that may not be immediately apparent.

Moisture and Humidity Effects

Water infiltration is particularly damaging to LED screens:

- Corrosion of electrical connections and circuit boards

- Short circuits that can damage multiple components

- Fogging or condensation on optical components

- Mold or fungal growth in humid conditions

Temperature Cycling Stress

Repeated heating and cooling cycles cause materials to expand and contract, leading to:

- Solder joint failures at connection points

- Mechanical stress on circuit boards

- Seal failures that allow moisture infiltration

- Adhesive degradation in laminated components

Chemical and Particulate Contamination

Industrial environments expose LED screens to various contaminants that can cause gradual degradation. Salt air near coastal locations, industrial chemicals, and airborne particles can all contribute to screen failure over time.

Control System Failures Disrupt Display Operation

The control systems that manage LED screen content and operation can fail independently of the display hardware. These failures often create confusing symptoms that require systematic troubleshooting.

Signal Processing Issues

Control system problems typically manifest as:

- No signal or “no input” messages

- Distorted or corrupted image display

- Incorrect color reproduction

- Timing issues that cause image tearing or artifacts

Software and Firmware Problems

LED screen control software can become corrupted or develop compatibility issues:

- Operating system crashes or freezes

- Driver software conflicts with updates

- Firmware corruption requiring reprogramming

- Network connectivity issues for remote-controlled displays

Communication Protocol Failures

Modern LED screens rely on digital communication protocols that can fail:

- Data transmission errors between controllers and displays

- Network latency issues affecting real-time content

- Protocol version mismatches between components

- Interference affecting wireless control systems

Age and Component Wear Reduce Screen Reliability

LED screens have finite operational lifespans, and component wear eventually causes performance degradation and failure. Understanding typical wear patterns helps predict when led repair or replacement becomes necessary.

LED Degradation Over Time

Individual LEDs gradually lose brightness and shift color over their operational lifetime:

- Blue LEDs typically degrade faster than red or green LEDs

- Brightness loss becomes noticeable after 50,000-100,000 hours

- Color temperature shifts affect the overall display appearance

- Uneven degradation creates brightness variations across the screen

Electronic Component Aging

Supporting electronics also have limited lifespans:

- Capacitors lose capacity and eventually fail

- Solder joints develop micro-cracks from thermal cycling

- Cable insulation degrades and becomes brittle

- Connector contacts oxidize and increase resistance

Maintenance Impact on Lifespan

Regular maintenance significantly extends LED screen operational life:

- Cleaning removes contaminants that accelerate degradation

- Ventilation system maintenance prevents overheating

- Connection inspections identify problems before failure

- Software updates address compatibility and performance issues

Extending Your LED Screen’s Operational Life

Understanding these common failure modes enables proactive measures that extend LED screen reliability and reduce unexpected downtime.

Regular inspection schedules, proper environmental controls, and prompt attention to early warning signs can prevent minor issues from becoming major failures.

Professional troubleshooting becomes essential when multiple failure modes interact or when specialized diagnostic equipment is required. However, many screen issues can be prevented through proper installation, regular maintenance, and attention to environmental factors that stress LED components.

When led repair is necessary, early intervention often reduces costs and downtime compared to waiting until complete failure occurs. Documenting screen performance over time helps identify degradation trends and plan maintenance activities before critical failures disrupt operations.