A high-performance welding workshop depends on more than just skilled hands and the right tools. The foundation of every precise weld and safe project often starts with something surprising—the welding table itself.

Whether you’re fabricating complex assemblies or tackling daily repairs, your welding workbench shapes outcomes for precision, efficiency, and safety.

This post explores how investing in a well-designed welding table can transform the quality of your work. We’ll break down essential design features, discuss how tables impact welding safety, and explain why leading suppliers such as BTH Sales are trusted by professionals seeking heightened performance.

By the end, you’ll understand what sets apart a standard workbench from a purpose-built precision welding table.

The Role of the Welding Table in Workshop Environment

Beyond a Surface to Weld On

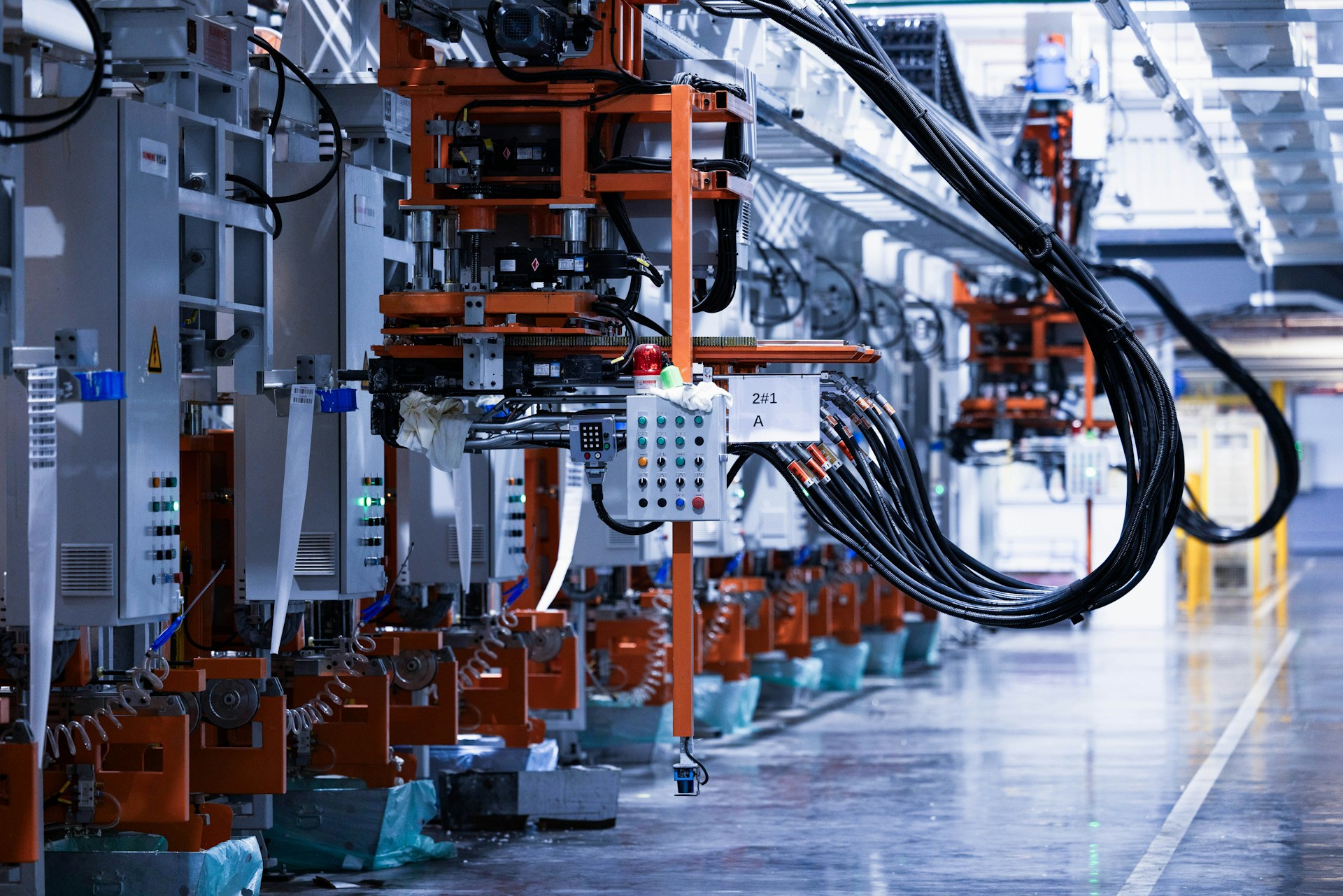

A welding table isn’t just a flat platform. It forms the structural basis of any welder’s workspace. The right surface supports workpieces, fixtures, clamps, and jigs while enduring high heat and heavy loads.

Professional tables feature heavy-duty steel construction and reinforced legs to minimize vibrations. This stability enhances weld consistency, especially during multi-pass or long seams.

Supporting Productivity and Workflow

Welders who work with robust tables notice less downtime and increased accuracy. A professional-grade welding workbench organizes the area efficiently, supporting tool storage and easy clamp access. This encourages a tidy, organized workflow, and reduces mishaps and wasted motion.

Precision Benefits of a High-Quality Welding Table

Maintaining Flatness and Alignment

Precision welding demands flat and true surfaces. Tables made by suppliers like BTH Sales are engineered to resist thermal distortion and warping. The result? Jigs and fixtures hold materials as intended, ensuring welds line up every time.

Even slight curves can misalign parts, creating costly errors. With a precision welding table, fabricators can guarantee reliable squareness and parallelism in assemblies.

Repeatable Results for Complex Setups

Complex projects, such as multi-component frames or fixtures, require repeatability. Modular tables with grid systems or T-slots allow welders to replicate setups accurately. This is vital for custom fabrication as well as small production runs.

Consistency is the mark of a true craftsman. By relying on a professional welding workbench, teams reproduce their best results, even across different operators.

Enhancing Welding Safety Every Step of the Way

Stable Support for Workpieces

Uneven, wobbly tables can create hazards. Heavy steel plates, pipes, or awkward shapes can tip, fall, or shift during welding, leading to injury. A quality welding table keeps every component stable across a variety of positions.

Integrated Safety Features

Bench design impacts ergonomics. Tables with adjustable height, edge guards, and heat-resistant coatings protect welders from burns, fatigue, and strain. Some models even include built-in fume extraction ports, improving workshop air quality.

By making safety part of the equipment selection process, workshops reduce accidents, downtime, and worker injury rates.

Key Features That Distinguish the Best Welding Tables

Material Matters

Quality starts with materials. Premium workbenches use thick, high-carbon steel or alloy top plates, with welded seams for extra durability. This ensures the table won’t bow or degrade under repeated heat cycles.

Practical Accessories

Look for built-in rulers, gridlines, lift-out sections, and adjustable stops. These extras help secure irregular parts or accommodate unique project needs. Tool holders, storage shelves, and cable management systems further streamline the workflow.

Suppliers like BTH Sales often customize welding workbench accessories, enabling buyers to select features matching their precise requirements.

The Connection Between Quality Equipment and Welding Efficiency

Reduced Setup Times

A premium welding workbench is more than a static platform. The best models speed up part placement and clamping, minimizing time spent on adjustments. Welders can move from setup to execution much more quickly.

Minimized Errors and Rework

When your surface is flat and your materials are secure, there’s less risk of distortion, insufficient weld penetration, or missed alignment. These improvements reduce the likelihood of rework, letting jobs finish on-time and within budget.

Selecting a Welding Table That Fits Your Unique Needs

Capacity for Expansion

Every shop is unique. Some require compact benches for tight spaces, while others need extensive modular systems that adapt to changing project demands.

Tables from trusted names like BTH Sales are designed to grow with your business, supporting everything from single prototypes to large-scale production.

Assessing the Return on Investment

While high-quality tables can represent a larger up-front investment, consider what you’re saving in lost time, errors, and repairs. Improved safety reduces workplace injuries, while precision lowers material waste. Over years of use, the benefits quickly outweigh the costs.

Getting More From Your Welding Workbench Investment

A professional welding table is the foundation upon which accuracy and safety are built. Shops that prioritize quality equipment not only deliver better results but also elevate worker safety and morale.

If you want to achieve consistent, high-precision welding, reduce costly mistakes, and create a safer workspace, it’s time to rethink your approach.

Evaluate your current welding workbench. Is it holding you back from your best work? Upgrading to a purpose-built table from a reputable supplier is an investment in productivity and peace of mind.