Pile driving is a critical construction process, but it comes with inherent risks. Without proper precautions, accidents can occur, potentially leading to injuries, property damage, or project delays.

This blog highlights the best practices in pile driving and installation to ensure safety and compliance during every stage of the project.

By following these guidelines, contractors can maintain a secure work environment and uphold industry standards while achieving optimal project outcomes.

Understanding the Basics of Pile Driving and Installation

Pile driving involves driving piles (structural elements) into the ground to provide foundational support for buildings, bridges, and other structures.

The installation process often requires heavy equipment, precise calculations, and strict adherence to safety protocols. Below are the essential components you must consider before beginning the pile driving process:

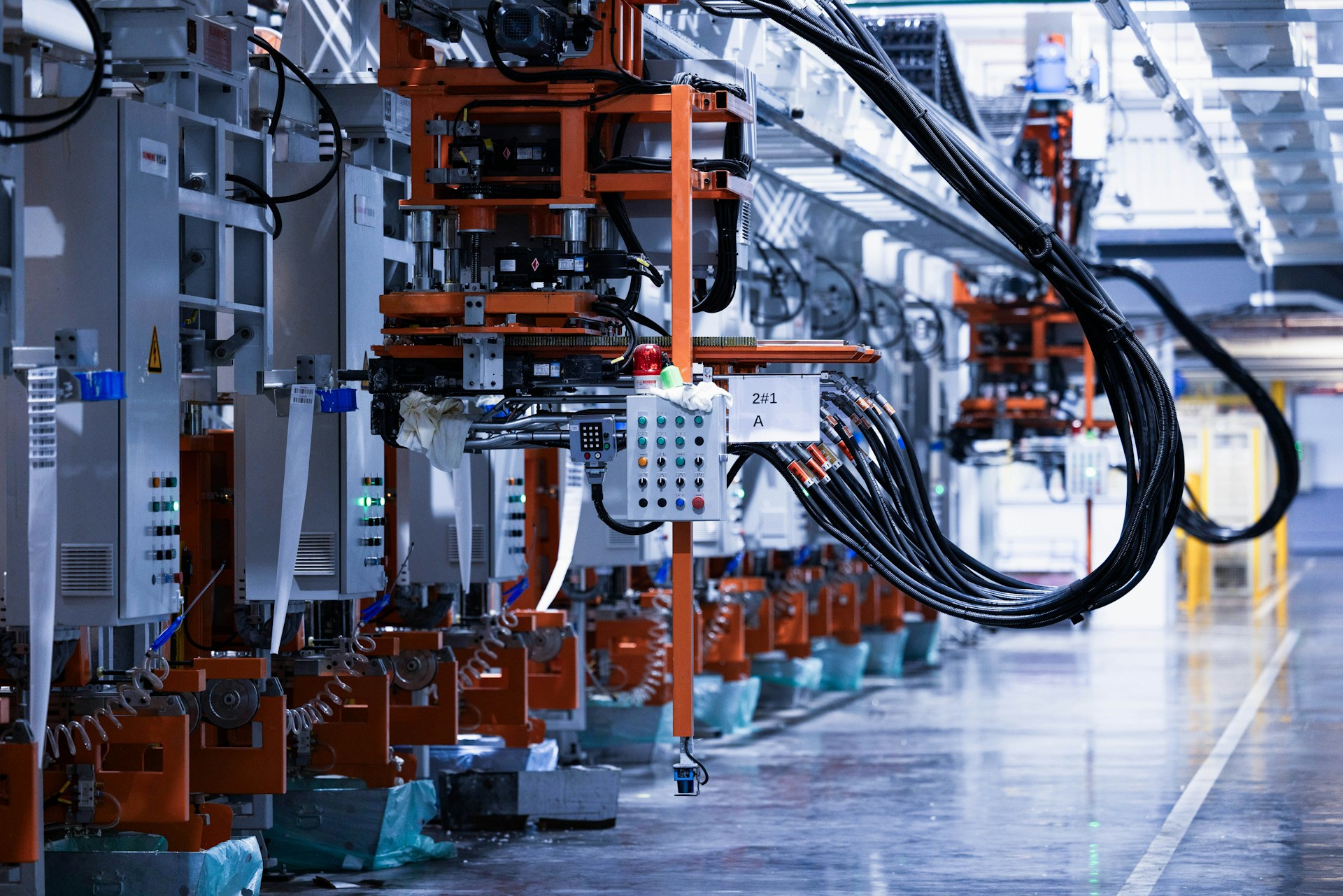

The Role of Equipment

Efficient and well-maintained equipment is the backbone of a successful pile driving operation. Components like pile drivers, driving helmets, and cranes must be operated by trained professionals.

Choosing the right equipment for the job ensures that the project completes successfully without machinery-related errors or safety concerns.

6 Key Safety Practices in Pile Driving and Installation

1. Proper Site Preparation

Pre-Construction Planning

Thorough site preparation is critical to reduce hazards. Conduct a comprehensive site assessment to identify potential risks, such as unstable soil conditions or underground utilities. Incorporating these findings into your project plan can prevent accidents during pile installation.

Establishing Safety Zones

Create clearly marked safety zones around the worksite to limit access to non-essential personnel. This minimizes the risk of injuries from falling debris or moving equipment.

2. Using the Right Equipment

Conduct Regular Inspections

Before operation, all pile driving equipment must undergo a thorough inspection. Look for signs of wear and tear or any potential malfunction that could compromise the safety of your team. Ensure the equipment’s compliance with local safety regulations.

Ensure Proper Operator Training

Equipment should only be handled by licensed and certified operators. Conduct safety training sessions to ensure the entire team knows how to use the machinery correctly and what to do in an emergency.

3. Implementing Worker Safety Precautions

Personal Protective Equipment (PPE)

Provide all workers with appropriate PPE, including hard hats, high-visibility vests, gloves, and steel-toed boots. Hearing protection is also essential, as pile driving machinery can produce extremely loud noise levels.

Establishing Clear Communication

Poor communication is a leading cause of workplace accidents. Use radios, hand signals, or other pre-established communication methods to ensure seamless coordination among team members, especially during critical tasks like pile installation.

4. Monitoring Environmental Conditions

Weather Considerations

Adverse weather can significantly impact pile driving safety. High winds, heavy rain, or lightning can increase the risk of accidents, so always monitor forecasts before starting work. Halt operations in conditions that could jeopardize safety.

Ground Stability

Perform soil testing to ensure the ground is stable enough to accommodate pile-driving activities. Weak or shifting soil can cause machinery to lose balance, creating hazards for workers on-site.

5. Ensuring Regulatory Compliance

Adhering to Local Codes

Strict compliance with local and international safety standards is non-negotiable. Regulatory bodies often specify guidelines for equipment usage, worker safety, and operational procedures, which must be followed to avoid penalties or project delays.

Maintaining Documentation

Keep detailed records of equipment inspections, safety meetings, and worker certifications. This not only ensures compliance but also acts as vital documentation in the event of an audit.

6. Conducting Post-Operation Inspections

Assessing Installed Piles

After pile installation, perform thorough inspections to ensure that all piles have been installed correctly and securely. Use advanced technology like pile integrity testing to verify their stability.

Evaluating Site Safety

Review the worksite for potential hazards after completing the operation. Ensure that leftover materials, unused equipment, or debris are removed to maintain a safe environment for other on-site teams or future phases of the project.

Take the Right Steps for Safe Pile Driving

The safety practices highlighted above ensure that pile driving and installation projects run smoothly, minimize risks, and adhere to top-tier industry standards.

From proper site preparation and equipment inspections to regulatory compliance and post operative evaluations, safety must remain a priority throughout the project lifecycle.

Remember, a safe worksite is a productive worksite. By focusing on worker well-being and project integrity, you can deliver results that exceed expectations while protecting everyone involved.

For more expert insights or equipment recommendations, connect with Pilecap. a certified pile driving consultant, today. Prioritize safety, it’s the foundation of every successful project.